(Selelekela)

Lefatšeng la liphaephe le li-tubing, ho na le mekhoa e mengata e fapaneng ea tlhahiso, e 'ngoe le e' ngoe e na le litšobotsi tsa eona le lisebelisoa. Har'a tsena, Electric Resistance Welding (ERW) e hlahella e le mokhoa o hlahelletseng oa ho hlahisa lipeipi tsa tšepe. Empa hantle-ntle peipi ea ERW ke eng? Ho utloisisa tlhaloso ea pipe ea ERW ho bohlokoa ho mang kapa mang ea amehang liindastering tse itšetlehileng ka mekhoa ea lipeipi e matla le e ka tšeptjoang. Poso ena ea blog e tla shebisisa lintlha tsa phala ea ERW, e hlalosang ts'ebetso ea eona ea tlhahiso, melemo, lits'ebetso, le hore na ke hobane'ng.'sa karolo ea bohlokoa mafapheng a fapaneng.

(E hlalosa Pipe ea ERW)

Ha re qaleng ka tlhaloso ea peipi ea ERW. ERW e emetse Electric Resistance Welding. Pipe ea ERW ke mofuta oa phala ea tšepe e entsoeng ka ho tjheseletsa seam ea lesela la tšepe kapa khoele ka bolelele ho sebelisa khanyetso ea motlakase. Ho fapana le liphaephe tse se nang moroko, tse entsoeng ka tšepe e le 'ngoe, liphaephe tsa ERW li entsoe ka ho thatela lesela le bataletseng hore e be cylindrical ebe e kopanya mathōko.

(Mokhoa oa Tlhahiso: Ho Shebella Haufi)

Mokhoa oa ho etsa lipeipi tsa ERW o kenyelletsa mehato e mengata ea bohlokoa:

Tokiso ea tšepe: Lithapa tsa tšepe tsa boleng bo phahameng kapa li-coil li khethoa ho latela lintlha tse lakatsehang tsa phala.

Ho theha: Lesela la tšepe le etsoa butle-butle ho ba sebopeho sa cylindrical ho sebelisa letoto la lirolara.

Welding: Mona ke moo boselamose ba "Motlakase Resistance Welding" bo etsahalang. Likarolo tsa cylinder e entsoeng li bokelloa hammoho, 'me motlakase oa motlakase o phahameng o feta ho bona. Ho hanyetsa hona joale ho hlahisa mocheso o matla, o qhibilihisang mathōko le ho a kopanya, ho etsa hore ho be le tjheseletso e matla, e longitudinal.

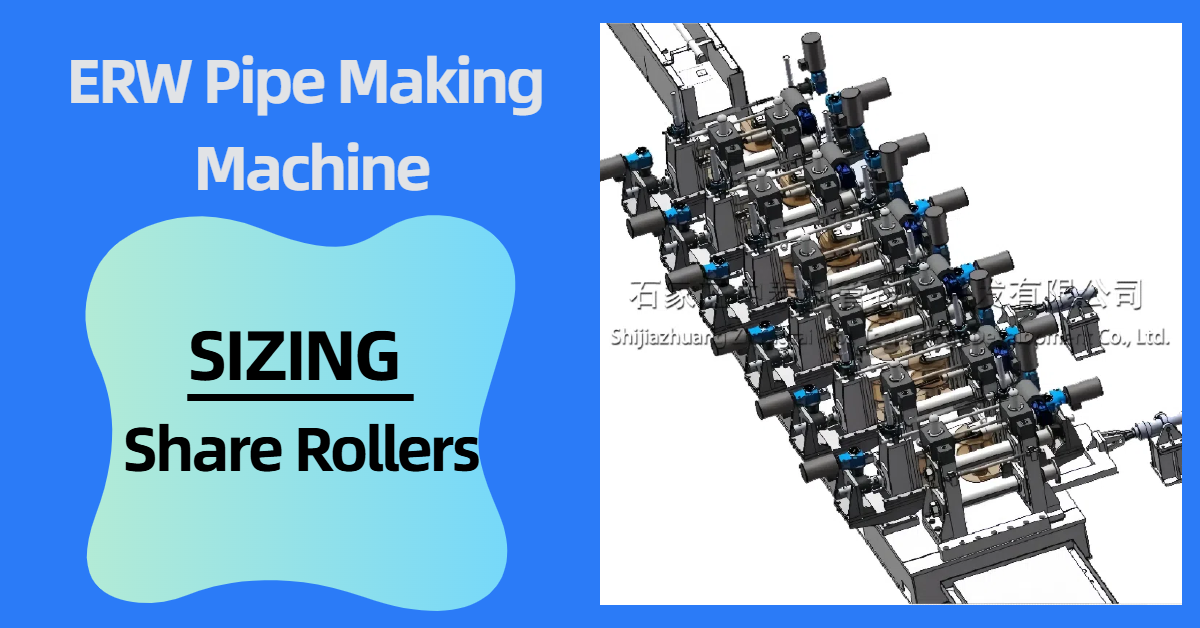

Sizing le Shaping: Ka mor'a ho tjheseletsa, phala e feta ka har'a lirolara tsa boholo ho fihlela bophara bo lakatsehang le sebopeho.

Ho Seha le ho Qetella: Peipi e ntan'o khaoloa ho ea bolelele bo hlokahalang 'me e etsoa mekhoa ea ho qetela e kang ho phunya, ho otlolla le ho hlahlojoa.

(Melemo ea ERW Pipe)

Pipe ea ERW e fana ka melemo e mengata e etsang hore e be khetho e tsebahalang lits'ebetsong tse ngata:

Katleho ea Litšenyehelo: Peipi ea ERW hangata e baballa litšenyehelo ho feta ha e bapisoa le phaephe e se nang seam, e etsang hore e be khetho e lumellanang le tekanyetso.

Botenya ba Lerako bo tsitsitseng: Ts'ebetso ea ERW e lumella taolo e nepahetseng holim'a botenya ba lerako la phala.

Matla a Hlollang a Weld: Mekhoa ea sejoale-joale ea ERW e hlahisa litšepe tse matla joalo ka, kapa tse matla ho feta tšepe ea motheo.

Mefuta e mengata ea boholo ba boholo: Pipe ea ERW e ka etsoa ka mefuta e mengata ea bophara le boholo.

Versatility: E loketse lits'ebetso tse fapaneng, ho tloha ho ts'ehetso ea sebopeho ho ea ho lipalangoang tsa metsi.

(Lisebelisoa tsa ERW Pipe)

Pipe ea ERW e fumana tšebeliso e pharaletseng liindastering le lits'ebetsong tse fapaneng:

Oli le Khase: Bakeng sa liphaephe, li-casings le li-tubing.

Kaho: E le likarolo tsa meralo meahong le mererong ea meralo ea motheo.

Lipalangoang tsa Metsi: Bakeng sa ho tsamaisa metsi libakeng tsa masepala le indastering.

Likoloi: Bakeng sa litsamaiso tsa ho ntša metsi le likarolo tse ling.

Manufacturing: Ka mekhoa e fapaneng ea indasteri e hlokang ho tsamaisoa ha mokelikeli kapa khase.

Scaffolding: E sebelisoa bakeng sa litsamaiso tse matla le tse bolokehileng tsa scaffolding.

(ERW Pipe vs. Seamless Pipe)

Leha liphaephe tsa ERW le tse se nang seamless li sebeletsa merero e ts'oanang, li fapana haholo ts'ebetsong ea tsona ea tlhahiso le litšobotsi. Liphaephe tse se nang moeli li fana ka matla a phahameng 'me hangata li khethoa bakeng sa lisebelisoa tse phahameng tsa khatello. Leha ho le joalo, liphaephe tsa ERW ka kakaretso li na le litšenyehelo tse ngata 'me li loketse mefuta e mengata ea lisebelisoa moo khatello e feteletseng e sa hlokeng. Ho utloisisa phapang pakeng tsa ERW pipe vs seamless pipe ho bohlokoa ha u khetha thepa e nepahetseng bakeng sa litlhoko tsa hau tse khethehileng.

(Seabo sa Thepa ea Tlhahiso)

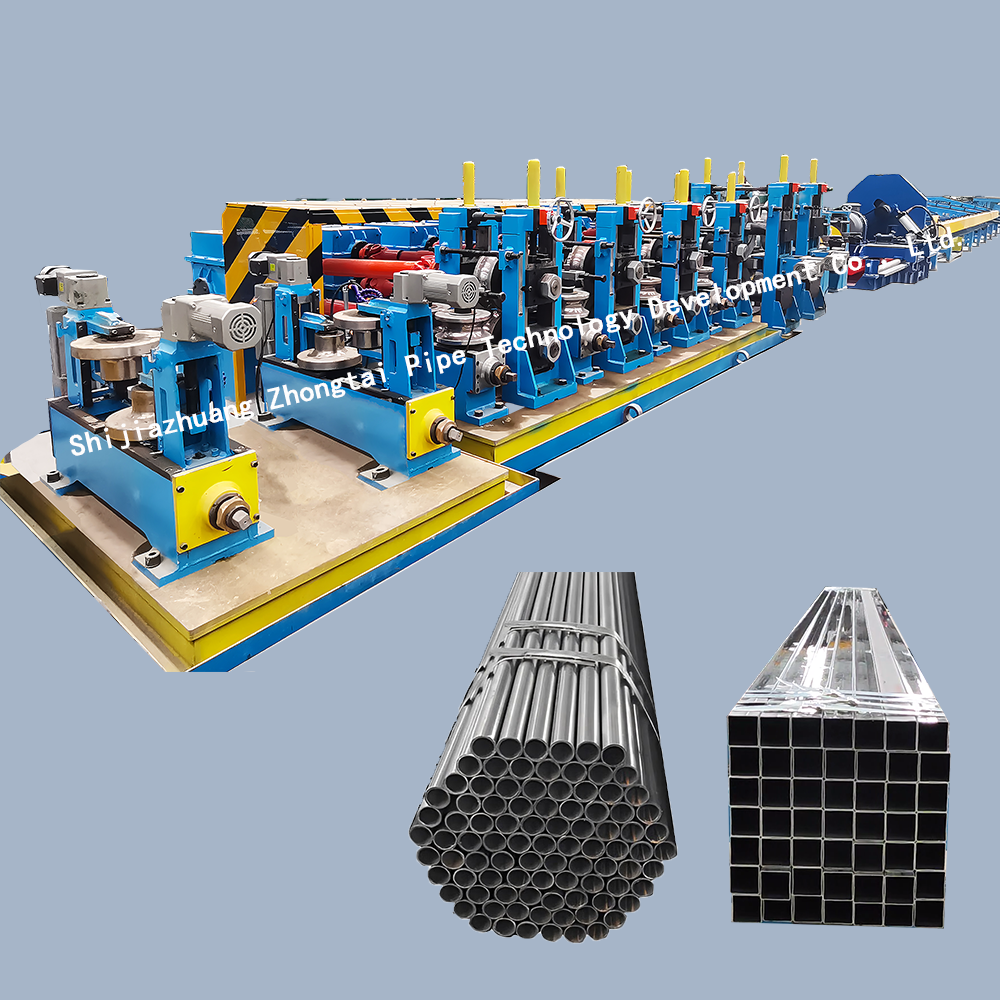

Ho hlahisa phala ea boleng bo holimo ea ERW ho itšetlehile haholo ka thepa e tsoetseng pele ea tlhahiso. Sena se kenyelletsa:

Li-Uncoilers le Li-Accumulators: Ho fepa likhoele tsa tšepe hantle moleng oa tlhahiso.

Ho theha Mills: Ho theha sekhahla sa tšepe butle-butle hore e be sebopeho sa cylindrical.

Mechini ea Welding: Pelo ea ts'ebetso ea ERW, e fanang ka welding e nepahetseng le e tšepahalang.

Sizing Mills: Ho netefatsa litekanyo tse nepahetseng tsa liphaephe.

Ho Seha Mechini: Ho seha phala ho fihlela bolelele bo lakatsehang.

Lisebelisoa tsa Tlhahlobo le Tlhahlobo: Ho etsa bonnete ba hore phala e finyella litekanyetso tsa boleng bo hlokahalang.

Haeba u batla ho etsa phala ea ERW, ho bohlokoa ho khetha thepa e nepahetseng.

(Qetello)

Ho utloisisa tlhaloso ea phaephe ea ERW le ts'ebetso ea ts'ebetso ea eona ho bohlokoa ho mang kapa mang ea sebetsang ka liphaephe tsa tšepe. Pipe ea ERW e fana ka tharollo e theko e boima le e fapaneng bakeng sa lits'ebetso tse fapaneng. Ka ho hlokomela melemo le mefokolo ea eona, u ka etsa liqeto u e-na le tsebo mabapi le hore na boitsebiso bona ba bohlokoa bo tla sebelisoa neng hona hokae. Ho feta moo, ho khetha thepa e nepahetseng ea tlhahiso ke ntho e ka sehloohong ho hlahisa liphaephe tsa ERW tse finyellang litekanyetso tsa indasteri le litebello tsa bareki.

(Call to Action)

Na u batla lisebelisoa tse ka tšeptjoang le tse sebetsang hantle tsa ho etsa lipeipi tsa ERW? Ikopanye le rona kajeno ho ithuta haholoanyane ka tharollo ea rona le hore na re ka u thusa joang ho ntlafatsa ts'ebetso ea hau ea tlhahiso!

Nako ea poso: Feb-19-2025