Ha basebelisi ba reka mochini o silang oa lipeipi tse cheselitsoeng, hangata ba ela hloko haholo katleho ea tlhahiso ea mochini o etsang lipeipi.Etsoe, litšenyehelo tse tsitsitseng tsa khoebo li ke ke tsa fetoha ka mokhoa o fokolang.Ho hlahisa liphaephe tse ngata tse finyellang litlhoko tsa boleng ka hohle kamoo ho ka khonehang ka nako e lekanyelitsoeng ho bolela ho theha melemo e mengata bakeng sa khoebo.Ka hona, matla a tlhahiso ea lipeipi tse cheselitsoeng ke e 'ngoe ea litekanyetso tsa ho reka thepa.

Joale, ke lintlha life tse amang matla a tlhahiso ea thepa?Na ts'ebetso ea mochini oa welding oa pipe e phahame ka ho lekaneng hore e khone ho hlahisa ka katleho kamoo ho neng ho lebelletsoe?

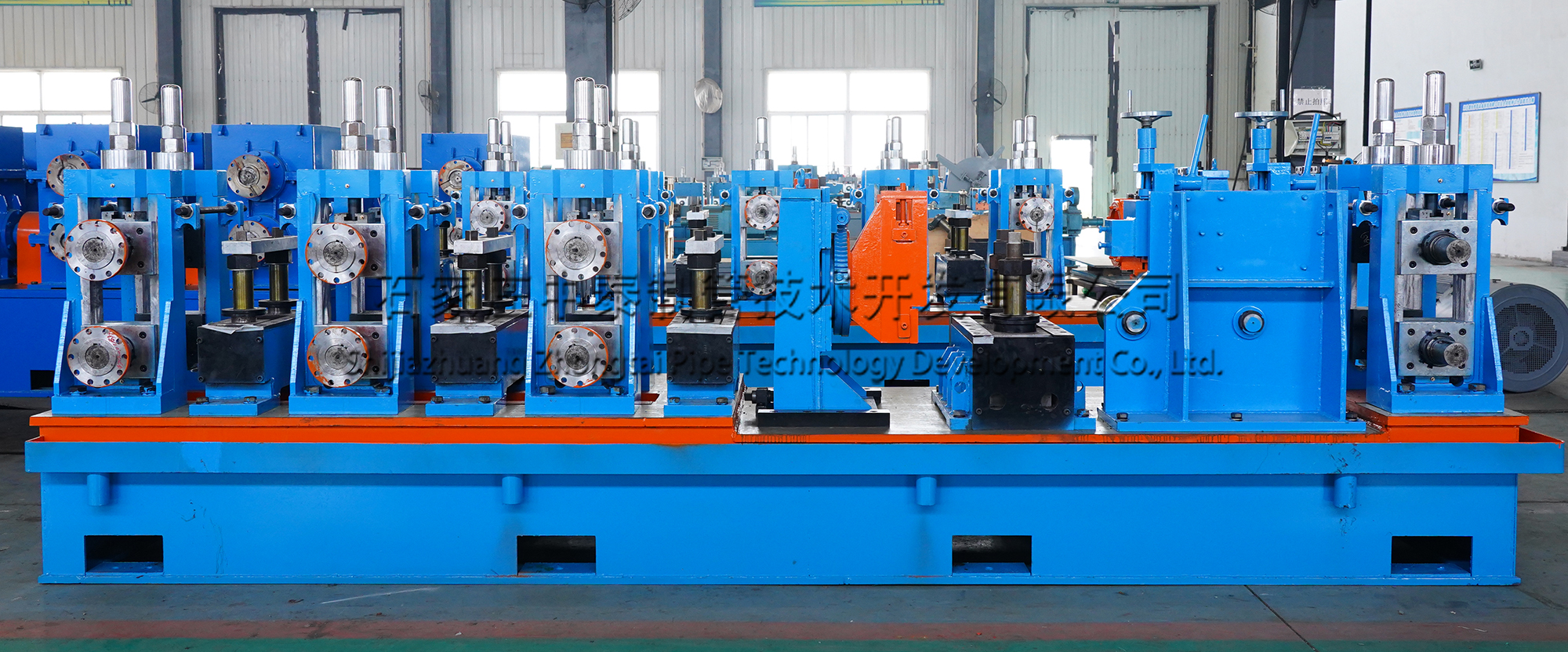

1. Boleng ba thepa ea mochine o etsang liphaephe

Boleng ba karolo ea ho etsa karolo ea lisebelisoa tsa lipeipi tse cheselitsoeng li ka nkoa ho tsoa likarolong tse peli.Ka lehlakoreng le leng, ke ho nepahala ha likarolo tse tsitsitseng tsa mochine le ho tšoarella ha thepa e sebelisoang.Pipe e cheselitsoeng e thehoa ka mokhoa oa ho etsa W, e leng mokhoa oa ho khutlisetsa lipotoloho ka hlobo.Haeba li-roller tse tšekaletseng le li-roller tse otlolohileng karolong ea ho theha li ke ke tsa sebetsa hantle, ho pota-pota ha liphaephe tse hlahisoang ho ke ke ha e-ba holimo, e leng ho tla ama ka ho teba mokhoa o latelang oa tlhahiso le ho fokotsa ka ho toba katleho ea kakaretso ea tlhahiso.

Ka lehlakoreng le leng, hore na ho nepahala le ho thatafala ha hlobo ho fihlile boemong ba ho sebetsa ka nako e telele ka katleho.Ho nepahala ha sebopeho sa lisebelisoa tsa lipeipi tse cheselitsoeng tse entsoeng ke ZTZG ho ka netefatsoa ka har'a ± 0.02mm.Mofuta o ts'oanang o entsoe ka thepa ea Cr12MoV, 'me ka mor'a mekhoa e nepahetseng ea 11, e tiisa ho nepahala le maemo a phahameng nakong ea tšebeliso.

2. Mochini oa ho tjheseletsa

Welding ke ts'ebetso ka mor'a ho theha, le hore na mochini oa welding o ka etsa welding stably hape ke ntlha ea bohlokoa e amang katleho eohle ea tlhahiso.A boleng bo phahameng tjheseletsa mochini ka boloka tjheseletsa eohle hona joale ka boemo bo tsitsitseng, 'me ha ho bonolo ho etsa hore perforation le mathata a mang tjheseletsa ka phala tjheseletsa ka lebaka la ho feto-fetoha ha hona joale,' me tlhahiso le tshebetso tlhahiso fetoha controllable.Ts'ebetso le boleng ba mechini ea welding e fanoeng ke ZTZG e amoheloa ke basebelisi ba ka sehloohong indastering.Kamora ho ntlafatsoa ke k'hamphani ea rona, ts'ebetso ea mohala oa tlhahiso e ba e loketseng haholoanyane litlhoko tsa tlhahiso ea lebelo le holimo.

Nako ea poso: Mar-18-2023